100L Vacuum Emulsifying Machine Emulsification machine For Cosmetics/Ointments

Product Details:

- Motor Power 3 Kilowatt (kW)

- Capacity (Ltr) 100 Liter (L)

- Product Type Emulsifying machine

- Volume 120 Liter (L)

- Cutting Speed 3000 RPM

- Click to View more

100L Vacuum Emulsifying Machine Emulsification machine For Cosmetics/Ointments Price And Quantity

- 17000 USD ($)/Set

- 15000.00 - 18000.00 USD ($)/Set

- 1 Set

100L Vacuum Emulsifying Machine Emulsification machine For Cosmetics/Ointments Product Specifications

- 3 Kilowatt (kW)

- 120 Liter (L)

- 100 Liter (L)

- Emulsifying machine

- 3000 RPM

100L Vacuum Emulsifying Machine Emulsification machine For Cosmetics/Ointments Trade Information

- 100 Set Per Month

- 30 Days

Product Description

Working Process:

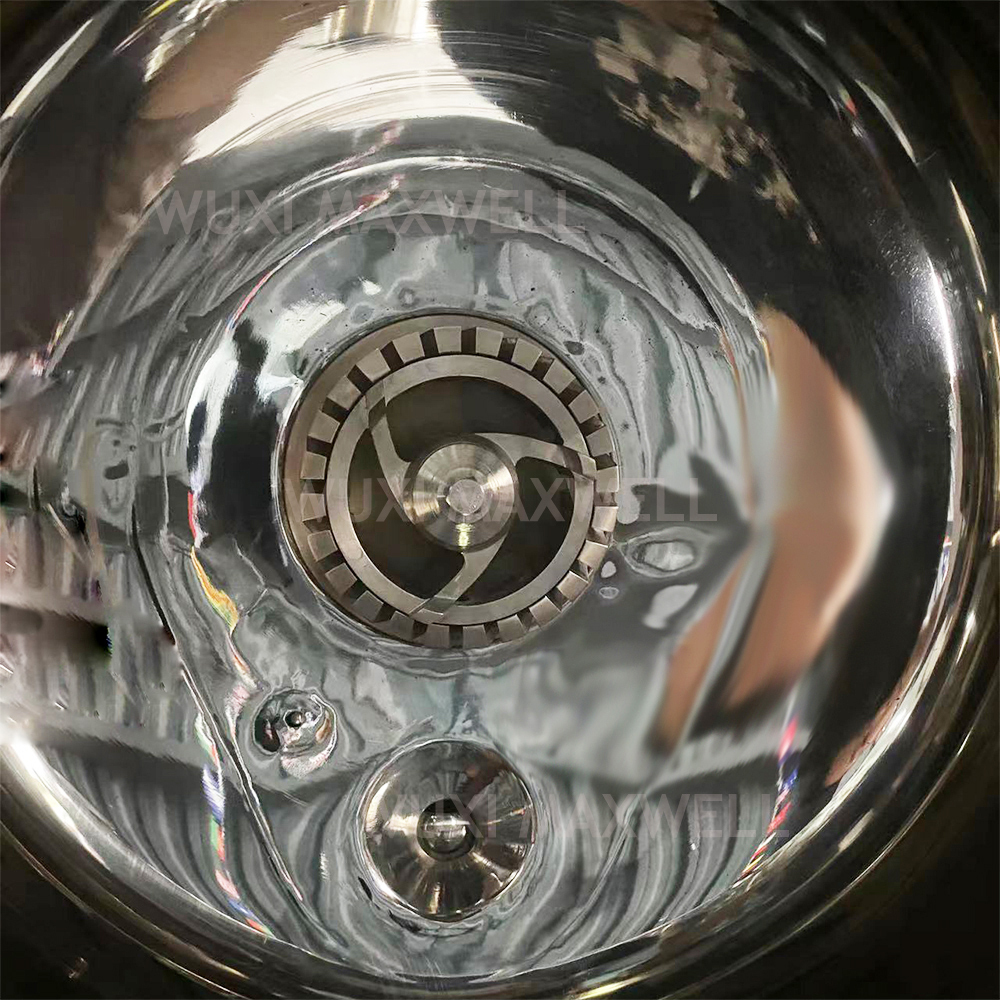

Put the materials into premix tank oil phase tank and water phase tank,after heated & mixed in water tank and oil tank, it can drawn the materials into emulsifying tank by vacuum pump. Adopting the middle stirrer & Teflon scrapers residues in emulsifying tank that sweep the residues on the wall of the tank to makes the materials wiped off become the new interface constantly. Then the materials will cut off, compressed and fold by the blades to stir, mix and run to the homogenizer. By the strong cutting off, impact and turbulent current from the high-speed shear wheel and fixed cutting case, the materials are cut off in interstices of stator and rotor and turn to particles of 6nm-2um promptly. Because the emulsifying tank is working under the vacuum state, the bubbles that produces in the process of mixing is taken away in time.

PERFORMANCES AND FEATURES:

1,The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.

2,The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindis soluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.

3,The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.

4,According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese